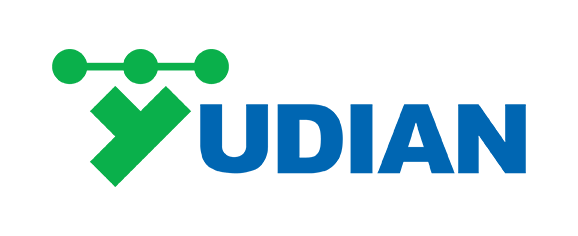

- APID Auto-Tuning Adaptive Technology

- Cascade Control Automatic Calibration Adaptive Technology

- Precise measurement and control, reducing customer energy consumption

- Flexible Modular Technology

- Low Power Consumption and Energy-Efficient Design

- High-Speed Sampling and High Anti-Interference Performance

- Reliable and Stable Performance in Complex Environments

- 0.001℃ High-Resolution Measurement Capability

- Flexible and Versatile Combinations

1、Automatic recognition of scene changes for precise control

Equipped with the PID parameter fault tolerance function, it can simulate expert strategies to adjust the PID controller’s operating state in response to various scenario changes on-site, such as changes in set points, pure time delay, additional disturbances, furnace door opening, or unexpected power outages. This ensures that precise control with no overshoot or undershoot can still be achieved on-site.

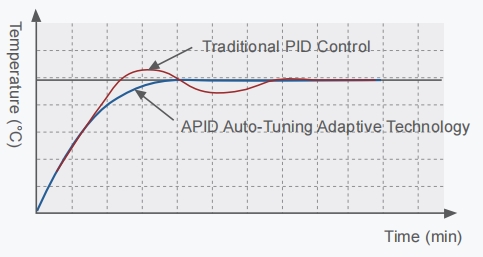

2、AAT advanced fast auto-tuning, saving debugging time

In addition to the classic AT auto-tuning function, the newly developed AAT advanced fast auto-tuning function analyzes the heating curve during equipment startup to calculate PID parameters. Unlike the traditional AT method, which requires oscillations back and forth, this significantly saves equipment debugging time.

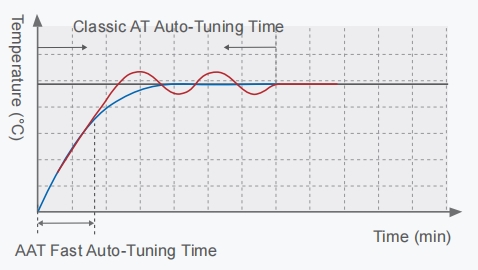

3、Powerful program control and curve fitting technology

The programmable instrument features multi-segment program control, enabling temperature control with any slope for heating/cooling. It includes programmable/operable commands such as jump (loop), run, pause, and stop, and allows modifications to the program during control operation. The system uses an AI-based regulation algorithm with curve-fitting functionality, ensuring smooth and stable curve control.

It can back up and store 10 groups of 50 segments of programs and offer the function of selecting multiple groups of program segments.

Allow for automatic switching between two sets of PID parameters based on the given set value SV.

TOP